Spot Check and Calibration of Test Equipment

- Share

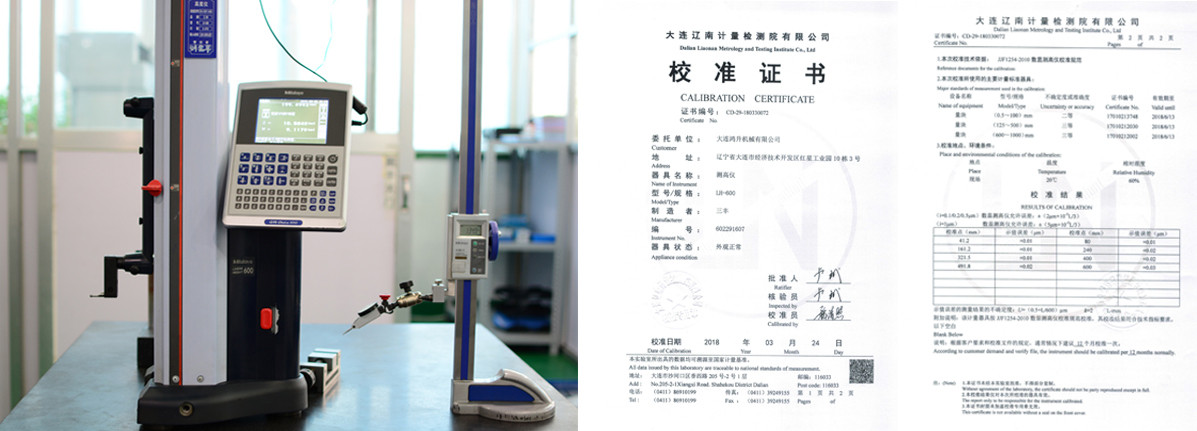

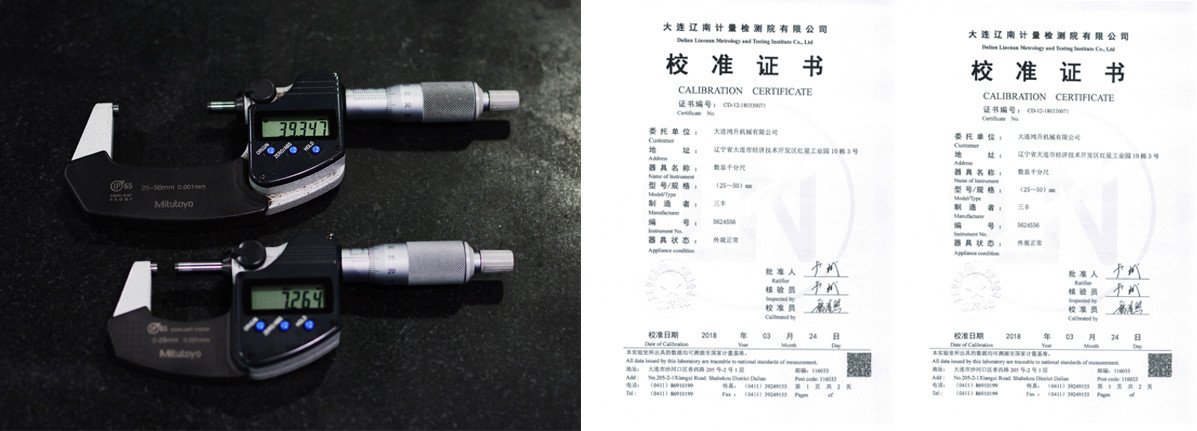

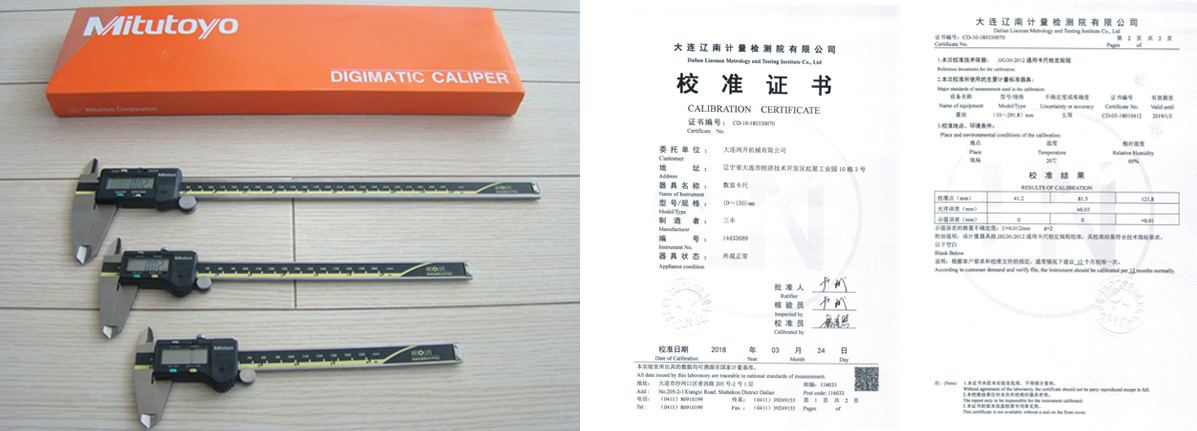

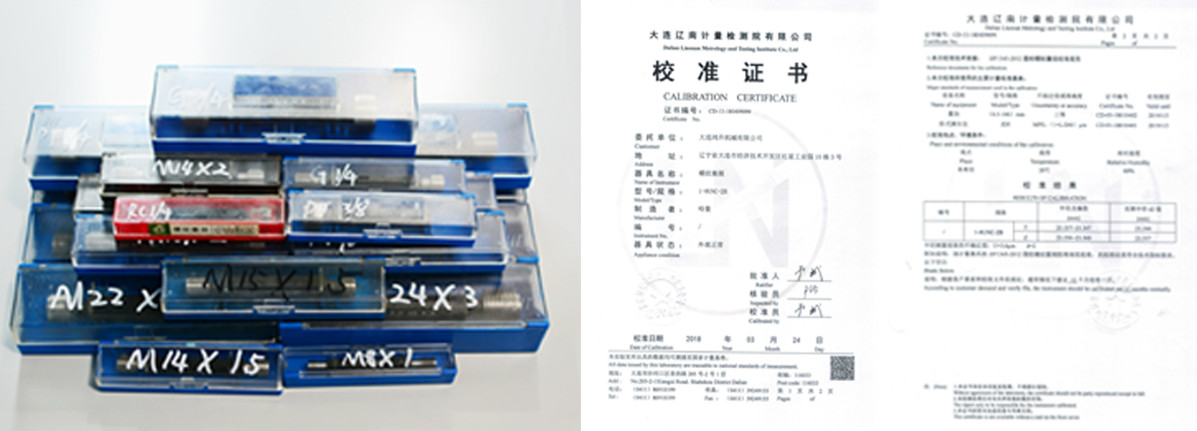

The company shall calibrate the inspection tools every 3-12 months.

The company shall calibrate the inspection tools every 3-12 months.  The surveyors should check the tools and record details on the checklist every day before testing.

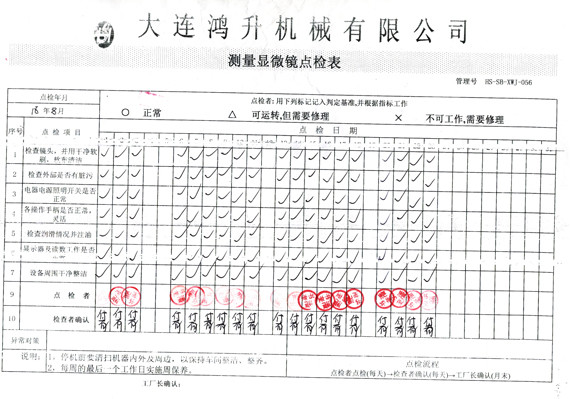

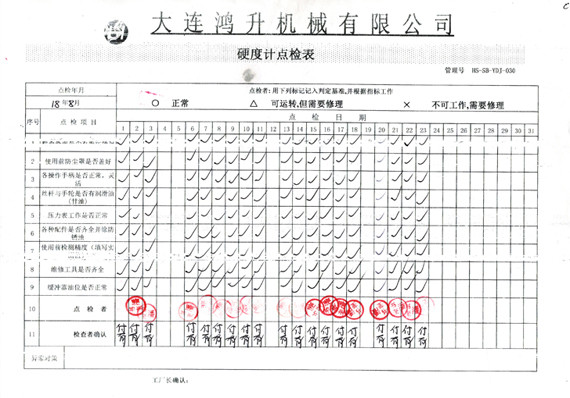

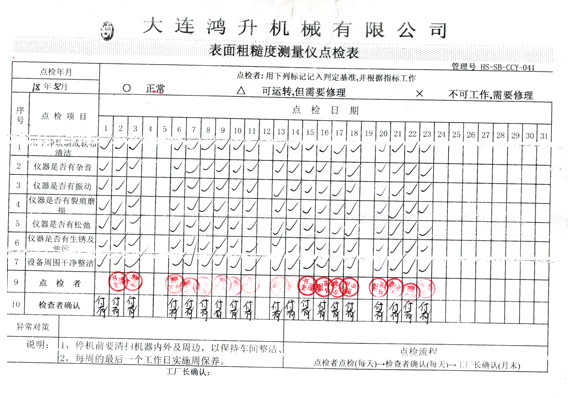

The surveyors should check the tools and record details on the checklist every day before testing.  The temperature in the quality inspection room is constant tempreature, the temperature is controlled at 20 degrees(±2 degrees).

The temperature in the quality inspection room is constant tempreature, the temperature is controlled at 20 degrees(±2 degrees).  The workpiece should be put in the testing room at a constant temperature of more than 4 hours then for inspecting.

The workpiece should be put in the testing room at a constant temperature of more than 4 hours then for inspecting.  The surveyors must have certain professional knowledge and practical work experience, and they need to meet the requirements of the products inspection. The surveyors should take an annual test to assess their testing abilities.Examination subjects include, testing principle, testing check, testing operation, intermediate testing, advanced testing and etc.Surveyors regularly participate in professional knowledge training, learn and accept advanced testing methods to improve their professional level.

The surveyors must have certain professional knowledge and practical work experience, and they need to meet the requirements of the products inspection. The surveyors should take an annual test to assess their testing abilities.Examination subjects include, testing principle, testing check, testing operation, intermediate testing, advanced testing and etc.Surveyors regularly participate in professional knowledge training, learn and accept advanced testing methods to improve their professional level.  Cleaning the measuring equipment and check the testing equipment before testing.

Cleaning the measuring equipment and check the testing equipment before testing.  The quality inspector must test the quality of the OEM machining parts strictly in accordance with the requirements specified in the drawings and technical documents.

The quality inspector must test the quality of the OEM machining parts strictly in accordance with the requirements specified in the drawings and technical documents.  In order to ensure that shipping 100% good machines machining parts to clients,we are strict with "First Article Inspection", "Inspection Tour", "Final Inspection'' ,integrating inspection workpiece with process control closely, controling the quality problems of each working procedure or possible quality problems strictly, eliminate bad products, make its can not be put into the next process or shipped out.

In order to ensure that shipping 100% good machines machining parts to clients,we are strict with "First Article Inspection", "Inspection Tour", "Final Inspection'' ,integrating inspection workpiece with process control closely, controling the quality problems of each working procedure or possible quality problems strictly, eliminate bad products, make its can not be put into the next process or shipped out.  Company requirements: all dimensions of all products are required to be checked except the customer's permission.

Company requirements: all dimensions of all products are required to be checked except the customer's permission.

|  |

| Three coordinate daily checklist tool microscope daily checklist | Tool microscope daily checklist |

|  |

| Hardness tester daily checklist | Surface roughness tester daily checklist |

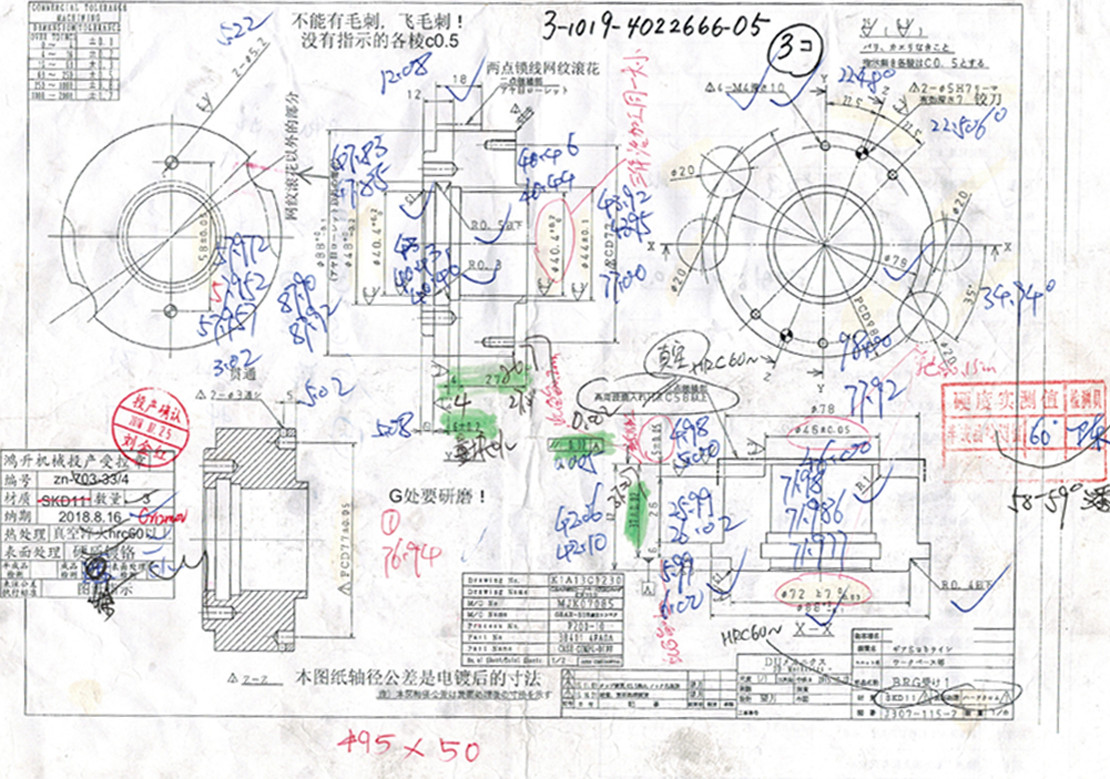

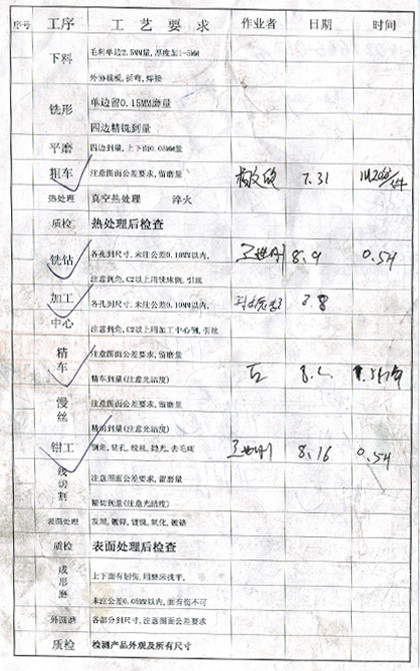

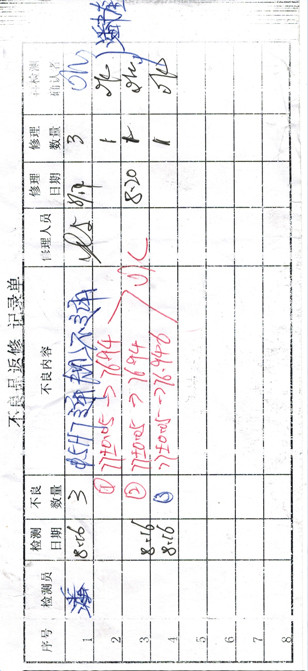

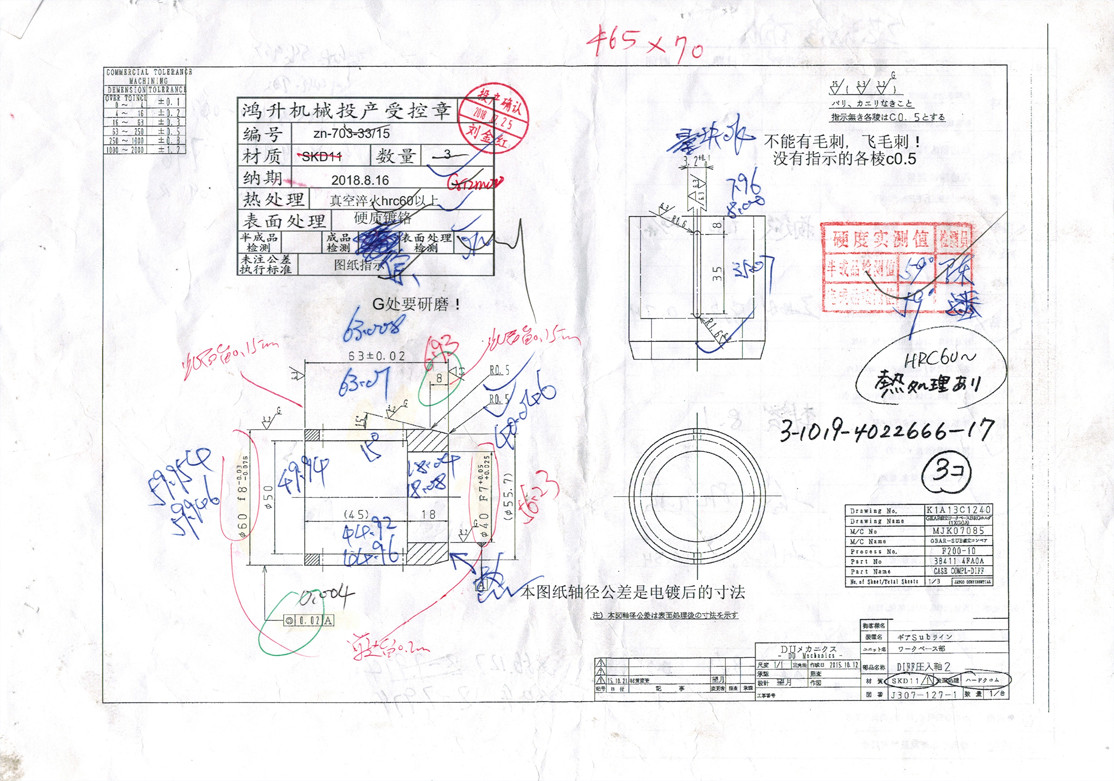

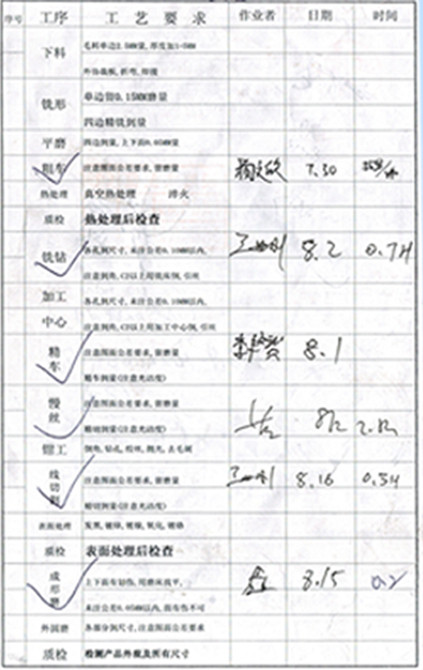

During the production process, production operators need to test the production parts by themselves, then record the verified result into the corresponding column in the process card for confirmation,and signed and record their own processing time, then surveyors must be strictly in accordance with the requirements of the drawings and technical documents provided for testing, after testing the parts size must be written in the book of the drawings, must strictly abide by tolerance, for non - conforming precision machining parts,precision cnc machining parts, surveyors need to record in the bad product list of repairing, then signed by the repair personnel after repair processing for second inspection.Data is recorded on the defect change list.The drawing cases after testing are as following:

Drawings after testing | ||

Confirmation on the Technological Process | Defective Products Record list | |

Drawings after testing | ||

Confirmation on the Technological Process | Defective Products Record list | |