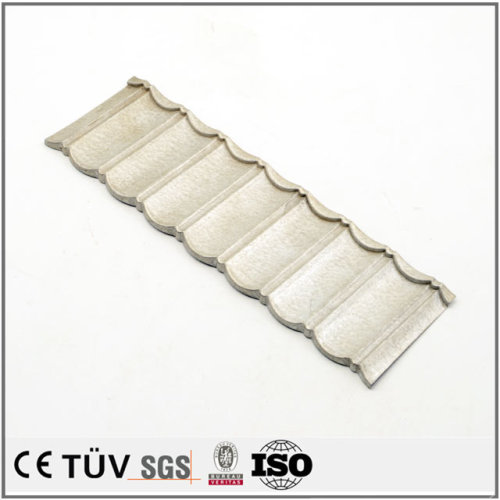

Sheet metal bending machining metal sheet enclosure parts

- Price

- US $0.5

- Model

- sheet metal bending parts

- MOQ

- 1 piece

Item specifics

- Name

- sheet metal bending parts

- Material

- steel

- Service

- OEM service

- Size

- As customer's requirement

- Quality Control

- Strict Testing Procedures

- Location

- Dalian,China

- Certificate

- ISO 9001:2008

- Application

- sheet mtal enclosure

Review

Description

Dalian Hongsheng Machine Co.,Ltd is located in the beautiful coastal city of Dalian, China. Hongsheng is a professional manufacturer specialized in the customized processing of high precision sheet metal and welding products such as machine tool protective cover, electric cabinet, tool cabinet, etc.The production of sheet metal parts is mainly used in electronics and electrical appliances, communications, automotive industry, medical equipment and other fields。At present, the company has 80 employees and more than 60 sets of high-precision equipment,Customers are mainly distributed in Japan, which accounts for 70% of the total production orders.By the end of 2018, the company has cooperated with 186 Japanese companies and more than 40 European and American companies...

| Item Name | Sheet metal bending machining metal sheet enclosure parts | |||||

| Quality Assurance | ISO9001:2008 Certified | |||||

| Main Equipment | Laser Cutting Machine/CNC Shearing Machine/Flat Bed Spot-welder/Die Grinder/Steel Processing Machine/Double Servo Turret-type Punch Press/Banding Machine/Steel Processing Machine/etc. | |||||

| Materials | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. | |||||

| Brass Alloy:3602 / 2604 / H59 / H62 / etc. | ||||||

| Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | ||||||

| Steel Alloy:Carbon Steel / Die Steel / etc. | ||||||

| Other Special Materials: Lucite / Nylon / Bakelite / etc. | ||||||

| We handle many other type of materials. Please contact us if your required material is not listed above. | ||||||

| Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting and so on | |||||

| Testing equipment | CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement | |||||

| Service | OEM/ODM/Customized/Design | |||||

| File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. | |||||

| Packing | 1,With plastic bag,with pearl-cotton package. | |||||

| 2,To be packed in cartons. | ||||||

| 3,Use glues tape to seal cartons. | ||||||

I.Test in production:

At the time of initial production, the top 10 products, all sizes of each product must be tested. inspecting 50 pieces or 100 pieces of sampling after debugging

II. Test on finished parts before shipping:

1.In principle, each product must be tested on where there are strict tolerances on the drawing. Spot check shall be carried out where there is no tolerance requirement 2.The quantity of sampling inspection is accordance with the products percentage, normally it shall not be less than 10% 3. Materials of all products shall be inspected 4. Surfaces on all products shall be inspected (including scratch, burrs, etc.) 5. All dimensions on sampling shall be inspected

DHL/UPS/FEDEX/TNT/OCS are shipped by default. If the cus tomer has demand, We can also choose express delivery according to customers' requirements.

Generally, it takes 3 days to send the express to Japan, and 4-5 days to Europe and America. This is mainly for small pieces (within 300kg).

For large parts, we will use air or sea transportation according to customers' requirements.

Generally, it takes 4-5 days to ship to Japan by air and 7-10 days to ship by sea. It takes 7-10 days to ship the goods by air in Europe and America, and 15-20 days to ship the goods by sea.