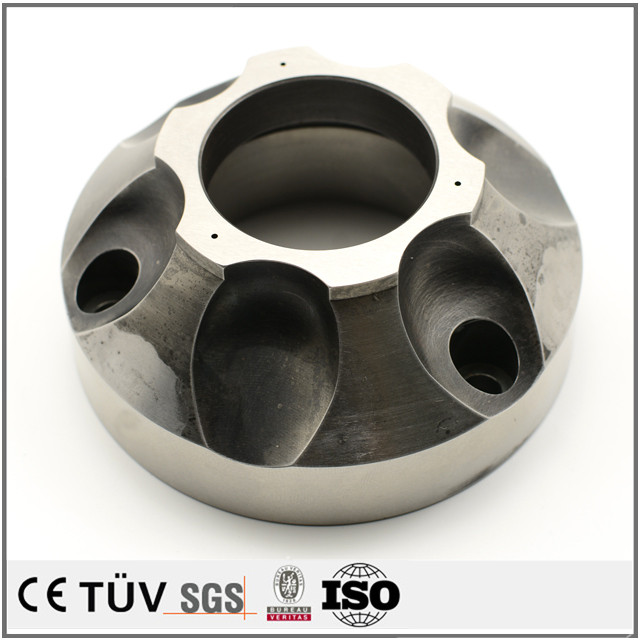

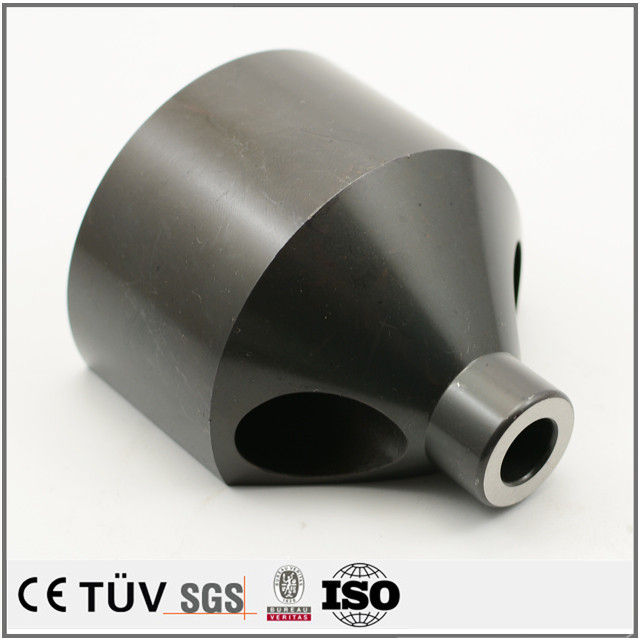

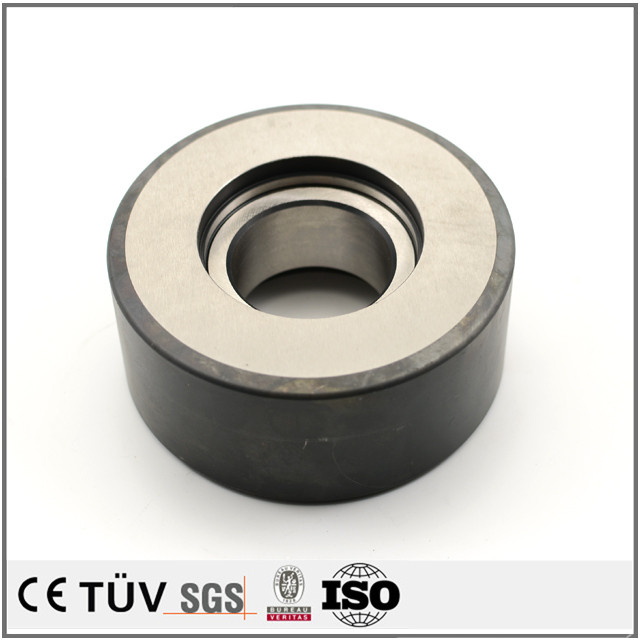

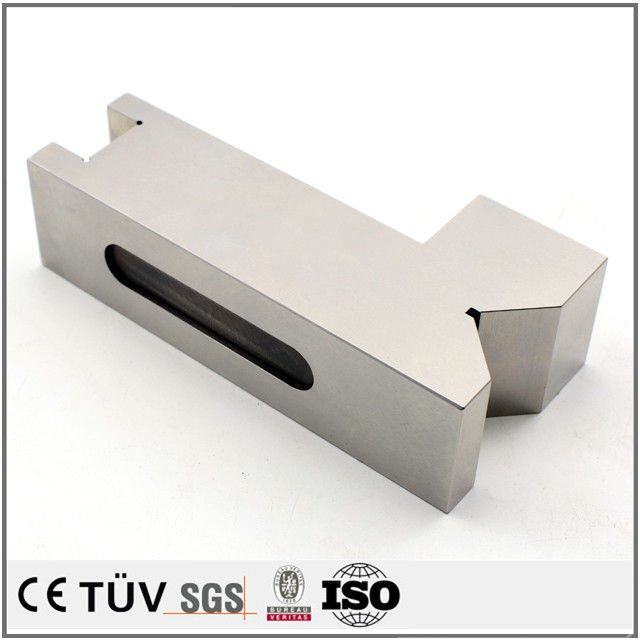

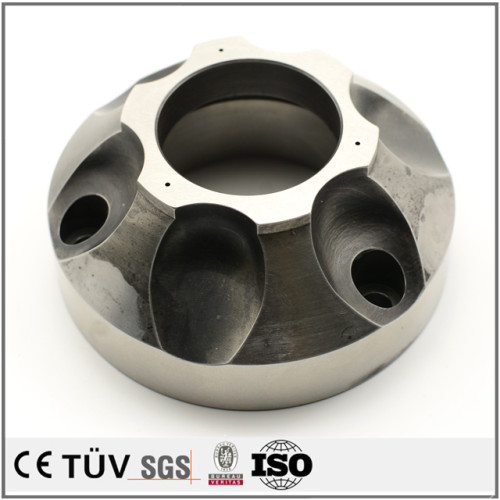

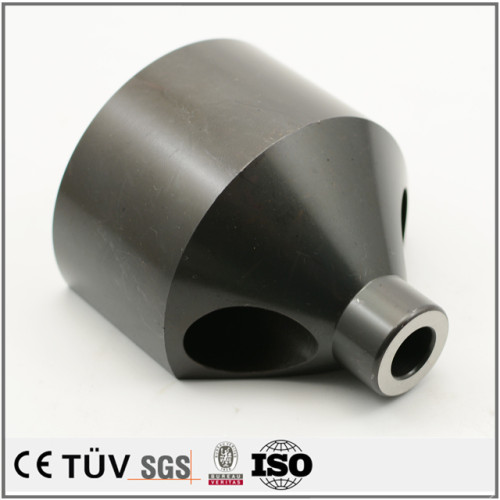

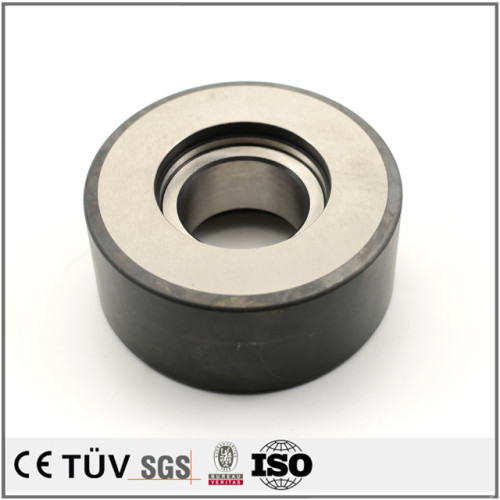

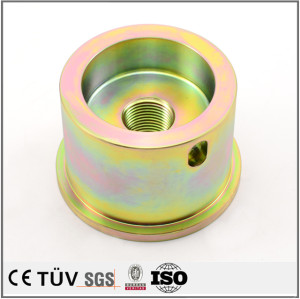

High quality OEM made quenching fabrication service machining parts

- Model

- quenching fabrication parts

Item specifics

- Material

- steel/aluminum

- process

- CNC machining

- Processing equipment

- Machining Center, CNC Lathe

- Surface treatment

- quenching

Review

Description

High quality OEM made quenching fabrication service machining parts

| Location | Dalian,China |

| Product Name | High quality quenching parts |

| QC | All products are inspected |

| Tolerance | Accuracy can reach 0.01mm |

| Certification | ISO9001:2008 |

| Service | OEM service |

Product description

| Material | The general materials can be supplied in the Chinese market. The materials not produced in the special Chinese market or the batch materials specially requested by customers are basically purchased through overseas material distributors in Shanghai and other places. The general material procurement cycle is 3-7 days. Special 7-15 days. |

| Application | The quenching process is widely used in the modern machinery manufacturing industry. Important parts in machinery, especially those used in automobiles, airplanes, and rockets, are almost quenched. |

| Main Machining Equipment | Our company has five-axis linkage machining center, turning and milling machine, machining center, CNC car, surface grinder, milling machine, laser cutting machine, wire cutting, electric discharge machine and other advanced processing equipment. |

| Testing Equipment | Japan's Mitutoyo's ternary, binary, Hexagon's three-dimensional measuring arm, altimeter, surface roughness tester, hardness tester and so on, the general measuring caliper micrometer rule block and so on. |

| Our advantage | 1,More than 50 production equipments, equipment technology covering, turning, milling, five-axis linkage cutting, grinding, discharging, slow wire, composite five-axis cutting, etc. There are 10 world-leading high-precision five-axis linkage devices, respectively, from the world. High-end brand DMG, Mazak. One-time completion of complex components can be achieved. The turning and milling composite five-axis linkage is a double-sided spindle. Automatically complete the station conversion of parts. |

| 2, We have a sound management system, have passed a large international certification: TUV.SGS BV, etc. | |

| 3, We have a very complete quality system, each product is a must for each size. The product is recorded and kept for 6 months. High-end equipment comes from Japan's Mitutoyo. | |

| 4,After nearly 20 years of history, the Hongsheng team has formed an army-based management system, a school-like growth environment, and a family-like warm team unity atmosphere. Hongsheng people have the literacy and technical ability to serve high-end customers around the world. | |

| 5,Communicate with Japanese, English, Russian, and Chinese. | |

| 6,The company has nearly 15 years of experience in overseas production and trade. Can handle some irregular circulation channels. |

Product display